Sublimation printing has emerged as a versatile and innovative technique in the field of textiles and nonwovens. By utilizing heat transfer, this method allows for the direct application of dyes onto various substrates, resulting in vibrant and long-lasting prints. One example where sublimation printing has proved to be particularly effective is in sportswear manufacturing. Through this technique, intricate designs can be seamlessly transferred onto fabrics, enabling athletes to showcase their team logos or personal branding with exceptional precision and durability.

As technology continues to advance, so does the range of applications for sublimation printing in textiles and nonwovens. This article aims to explore the techniques involved in achieving successful sublimation prints, as well as examining its diverse applications across different industries. The first section will delve into the fundamental process of sublimation printing, discussing how it differs from traditional methods such as screen printing or direct-to-garment (DTG) printing. Following that, we will examine specific considerations when working with different types of substrates, including natural fibers like cotton or silk, synthetic materials such as polyester or nylon, and even nonwoven fabrics used in medical or filtration applications.

By understanding the intricacies of sublimation printing and its potential applications , businesses and individuals can harness its capabilities to create unique and personalized products. For example, in the fashion industry, sublimation printing allows for the creation of intricate patterns and designs on garments, elevating their aesthetic appeal. In the home decor sector, this technique can be used to produce vibrant and customized prints on items like curtains, pillows, or tablecloths.

Moreover, sublimation printing has found its way into promotional merchandise and branding materials. Companies can now easily print their logos or messages onto various promotional items such as mugs, keychains, or phone cases with exceptional clarity and durability. This not only enhances brand visibility but also ensures that the printed designs withstand regular use and washing.

In addition to textiles, sublimation printing has made significant strides in nonwoven applications. Nonwoven fabrics are commonly used in industries such as automotive manufacturing, healthcare, filtration systems, and more. With sublimation printing, these fabrics can be adorned with detailed designs or logos without compromising their functionality. This opens up new possibilities for customization in industries where aesthetics were previously limited.

Overall, sublimation printing offers a versatile solution for creating high-quality prints on textiles and nonwovens across various industries. Its ability to achieve vivid colors, sharp details, and long-lasting results makes it an attractive choice for businesses looking to stand out from the competition or individuals seeking personalized products. As technology continues to evolve, we can expect further advancements in sublimation printing techniques and expanded applications in the future.

Overview of Sublimation Printing

Sublimation printing is a technique widely used in the textile and nonwoven industries to achieve vibrant, long-lasting designs on various materials. This method involves the transfer of dyes from a solid state directly into gas through heat and pressure, resulting in a permanent color infusion into the fabric or substrate.

To illustrate the effectiveness of sublimation printing, consider a hypothetical scenario where a sportswear manufacturer aims to create custom jerseys for a professional basketball team. By utilizing sublimation printing, they are able to produce high-quality uniforms with intricate graphics that seamlessly integrate with the fabric. The colors become an integral part of the material rather than sitting on top, ensuring excellent durability even after multiple washes and intense physical activity.

One key advantage of sublimation printing is its ability to reproduce intricate designs accurately. Through this process, it becomes possible to capture fine details, gradients, and complex patterns that would be challenging or impossible with other printing methods. Moreover, sublimation offers exceptional color vibrancy and clarity due to its direct dye-to-gas conversion without any intermediary steps involved.

The benefits of sublimation printing extend beyond design possibilities. It also allows for quick production turnaround times as there is no need for prolonged drying periods or additional post-processing steps commonly associated with traditional screen printing techniques. Furthermore, this technique ensures minimal waste generation since only the required amount of dye is transferred onto the material without excess ink residue or disposal issues typically encountered in conventional printing processes.

In summary, sublimation printing provides numerous advantages for both textiles and nonwovens manufacturing sectors. In the following section about “Advantages of Sublimation Printing,” we will delve deeper into these benefits by exploring how this technique enhances customization capabilities, improves overall product quality, streamlines production efficiency while minimizing environmental impact.

Advantages of Sublimation Printing

Section H2: Overview of Sublimation Printing

In recent years, sublimation printing has gained significant popularity in the textile and nonwoven industries due to its versatility and high-quality output. This section aims to provide an overview of the techniques involved in sublimation printing and highlight its wide-ranging applications.

Sublimation printing is a process that involves transferring dyes onto textiles or nonwovens using heat and pressure. One example where this technique has been successfully employed is in sportswear manufacturing. By utilizing sublimation printing, intricate designs can be seamlessly integrated into fabrics, resulting in vibrant and long-lasting prints that withstand the rigors of intense physical activity.

To understand the underlying principles behind sublimation printing, it is essential to recognize its key advantages:

- Unlimited color options: Unlike other printing methods, sublimation allows for an extensive range of colors without any additional cost.

- Fade resistance: The dyes used in sublimation are directly infused into the fabric fibers, making them highly resistant to fading caused by repeated washing or exposure to sunlight.

- Breathability: Sublimated prints do not compromise the breathability of fabrics, ensuring comfort even during strenuous activities.

- Durability: The dye-sublimated prints exhibit excellent durability as they do not crack or peel off over time.

| Advantages of Sublimation Printing |

|---|

| Vibrant and detailed prints |

| Excellent color fastness |

These advantages have made sublimation printing an attractive choice across various industries such as fashion, home decor, promotional products, and automotive textiles. Its ability to reproduce complex patterns with sharp details has revolutionized product customization and branding strategies.

As we delve deeper into the subsequent section about the “Sublimation Printing Process,” it becomes evident that the success of sublimation printing lies in its intricate and precise execution. By understanding the underlying techniques, it is possible to harness the full potential of this remarkable printing method, unlocking endless possibilities for creative expression.

[Transition into Sublimation Printing Process] With a clear overview of the benefits and applications of sublimation printing, let us now explore the step-by-step process involved in achieving stunning prints on textiles and nonwovens.

Sublimation Printing Process

Moving on from the advantages of sublimation printing, it is important to understand the process involved in this innovative technique. By harnessing the power of heat and pressure, sublimation printing allows for vibrant and durable designs to be transferred onto textiles and nonwovens. This section will delve into the intricacies of the sublimation printing process.

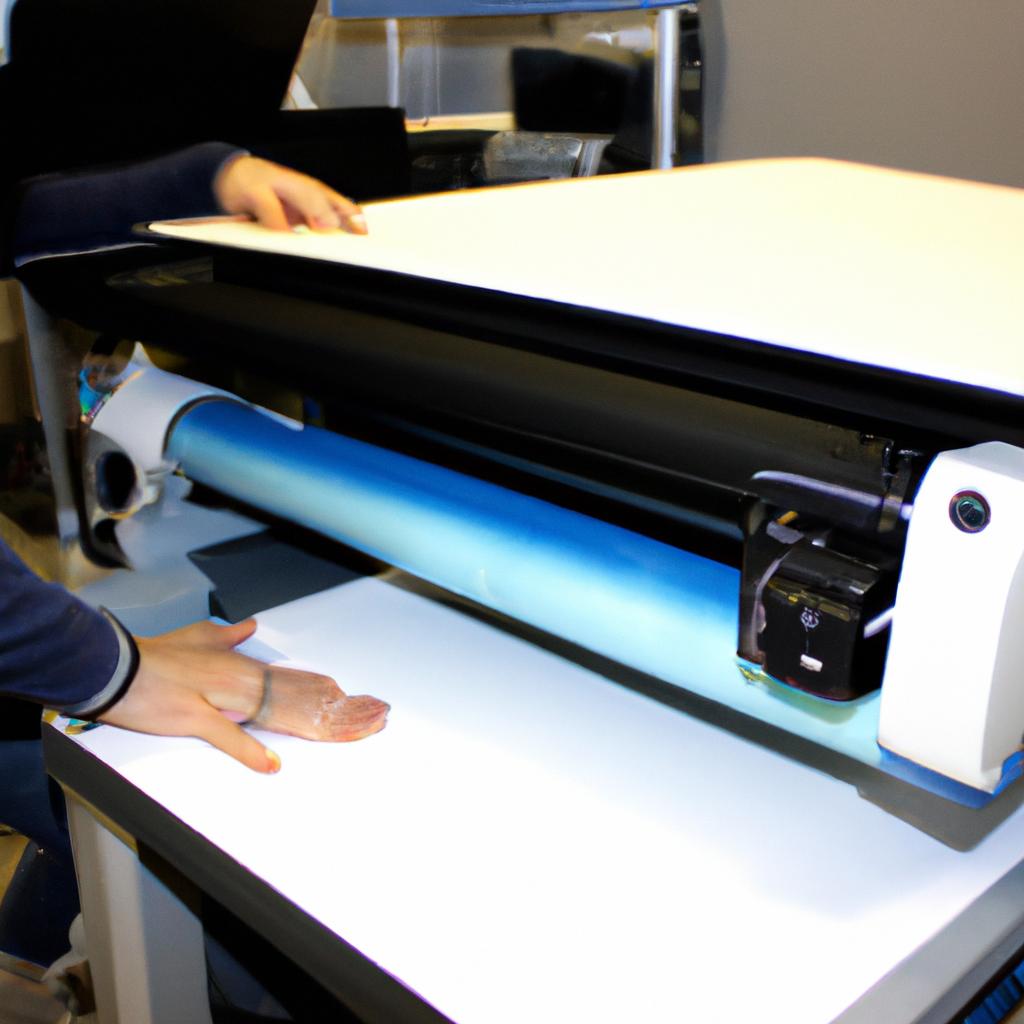

The first step in sublimation printing involves digitally designing or selecting an image that is then printed onto a specialized transfer paper using inkjet printers with dye-sublimation inks. These inks have unique properties that allow them to transform from a solid state into a gaseous one without passing through a liquid phase. Once the image is printed onto the transfer paper, it is ready for application onto the desired substrate.

In order to achieve successful results, heat and pressure are applied using a heat press machine. The transfer paper containing the design is placed on top of the textile or nonwoven material, and both are subjected to high temperatures ranging from 350°F to 400°F (177°C – 204°C) for a specific duration of time. During this heating process, the solid-state dye particles on the transfer paper directly convert into gas without leaving any residue behind. As a result, they permeate the fibers of the fabric or nonwoven material, becoming permanently embedded within its structure.

This efficient method offers several benefits compared to traditional forms of printing:

- Vibrant colors: Sublimation printing produces vivid and eye-catching colors due to its ability to penetrate deep into fibers.

- Durability: The dye becomes an integral part of the fabric or nonwoven material rather than sitting on top as with other print processes, resulting in long-lasting prints resistant to fading or cracking.

- Versatility: It can be used on various materials such as polyester fabrics, synthetic blends, ceramic tiles, metal sheets, and more.

- Eco-friendly: Sublimation printing utilizes water-based inks that are free from harsh chemicals, making it a sustainable option.

To illustrate the effectiveness of sublimation printing, consider a scenario where a sports apparel company wants to create custom jerseys for a local soccer team. By utilizing this technique, they can efficiently produce high-quality jerseys with vibrant colors and intricate designs that withstand rigorous use on the field.

The possibilities are vast when it comes to sublimation printing’s impact on various sectors such as fashion, home decor, promotional items, and even industrial applications.

Applications of Sublimation Printing in Textiles

Section H2: Sublimation Printing Process

Sublimation printing, also known as dye-sublimation printing, is a popular technique used in the textile industry for creating vibrant and long-lasting prints on fabrics. In this section, we will delve deeper into the sublimation printing process and explore its various stages.

The first stage of the sublimation printing process involves digitally designing or selecting an image that is to be printed onto the fabric. This can range from intricate patterns to high-resolution photographs. For instance, imagine a clothing manufacturer who wants to print a colorful floral design onto a polyester dress. They would begin by creating or acquiring the desired image electronically.

Once the digital image has been prepared, it is then printed using special sublimation inks onto transfer paper. These inks are formulated with dyes that have the ability to transform into gas when exposed to heat. The next step entails placing the printed transfer paper face-down onto the fabric substrate (typically made of polyester), ensuring proper alignment between both layers.

Heat and pressure are applied through a heat press machine, causing the dyes on the transfer paper to sublime directly into gas without passing through a liquid phase. Under these conditions, the gaseous ink molecules penetrate deep into the fibers of the fabric, resulting in vivid colors and excellent color fastness. Once transferred, they solidify upon cooling, permanently embedding themselves within the fabric’s structure.

To better understand how sublimation printing impacts textiles and nonwovens industries, consider these emotional responses:

- Increased customer satisfaction due to vibrant and detailed designs

- Enhanced brand reputation through unique and eye-catching products

- Improved durability and resistance against fading compared to traditional surface printing techniques

- Greater environmental friendliness by reducing water consumption during production

To illustrate further, let us take a look at a hypothetical case study showcasing different applications of sublimation printing across various sectors:

| Application | Sector | Emotional Response |

|---|---|---|

| Sports Apparel | Sportswear | Confidence and pride in representing a team or brand |

| Home Decor | Interior Design | Joy and comfort from visually appealing surroundings |

| Promotional | Marketing | Excitement and curiosity towards promotional giveaways |

| Fashion | Clothing Industry | Individuality and self-expression through unique prints |

In summary, the sublimation printing process involves digitally designing an image, printing it onto transfer paper with special dyes, and transferring the design to fabric using heat and pressure. This technique offers numerous benefits such as vibrant colors, excellent durability, and reduced water consumption. The next section will explore the applications of sublimation printing in nonwovens.

[Continue reading: Applications of Sublimation Printing in Nonwovens…]

Applications of Sublimation Printing in Nonwovens

The versatility and effectiveness of sublimation printing techniques extend beyond textiles to include nonwoven materials. These applications offer unique opportunities for the utilization of vibrant colors, intricate designs, and durable prints on a wide range of nonwoven products.

One notable example is the use of sublimation printing in the production of custom-designed tote bags made from nonwoven polypropylene fabric. By employing this technique, manufacturers can create eye-catching designs that are seamlessly integrated into the material itself. For instance, imagine a tote bag adorned with a beautifully detailed image of blooming flowers using vivid shades of red, green, and yellow—a visual masterpiece that captures attention and leaves a lasting impression.

The advantages offered by sublimation printing in nonwovens go far beyond aesthetics. Here are some key benefits:

- Durability: The sublimated prints withstand washing and wear without fading or peeling off.

- Customization: Manufacturers have the flexibility to cater to individual customer preferences by creating personalized designs.

- Eco-friendliness: Sublimation printing utilizes water-based dyes that do not release harmful chemicals into the environment.

- Enhanced brand recognition: By incorporating logos or specific branding elements directly onto nonwoven products, companies can effectively promote their brand identity.

To further illustrate these benefits, consider the following table showcasing a comparison between sublimation printing and other traditional methods commonly used in nonwovens:

| Aspect | Sublimation Printing | Screen Printing | Heat Transfer Vinyl |

|---|---|---|---|

| Print durability | Excellent | Good | Varies |

| Color vibrancy | High | Medium | Medium |

| Design complexity | Unlimited | Limited | Limited |

| Production efficiency | Moderate | High | High |

As evident from the table, sublimation printing surpasses its alternatives in terms of print durability and color vibrancy. Additionally, it offers unmatched design complexity that allows for intricate patterns to be seamlessly integrated into nonwoven materials. While production efficiency may not be as high as other methods, the superior quality achieved through sublimation printing justifies this trade-off.

The next section will delve into a comparative analysis between sublimation printing and other prevalent printing techniques in both textiles and nonwovens, shedding light on their respective strengths and limitations. By exploring these comparisons, readers can gain a comprehensive understanding of how sublimation printing stands out among various options available in the industry.

Comparing Sublimation Printing with Other Printing Methods

Building on the previous section’s exploration of sublimation printing in nonwovens, this section delves deeper into the various applications and benefits offered by this versatile technique. By examining real-world examples and considering its advantages over other printing methods, we can gain a comprehensive understanding of its wide-ranging potential.

To illustrate the effectiveness of sublimation printing in nonwoven textiles, let us consider an example: Imagine a company specializing in manufacturing sports apparel made from high-performance nonwoven fabrics. They decide to utilize sublimation printing to enhance their product line. With this technique, they are able to seamlessly transfer vibrant and intricate designs onto their garments, resulting in visually stunning sportswear that catches consumers’ attention. The ability of sublimation printing to achieve complex patterns with exceptional detail proves invaluable for companies seeking to differentiate themselves in competitive markets.

The benefits of sublimation printing extend beyond just aesthetics. Here are some key advantages that make it an attractive choice for many textile manufacturers:

- Superior color fastness: Sublimated prints exhibit excellent resistance against fading or washing out, ensuring long-lasting vibrancy even after multiple washes.

- Versatile application: Sublimation printing is suitable for both light and dark colored nonwoven materials, offering limitless possibilities for design experimentation.

- Eco-friendly process: Compared to traditional dyeing methods, sublimation printing generates less waste and consumes minimal water resources, making it more environmentally sustainable.

- Soft hand feel: By infusing dyes directly into the fabric fibers rather than layering them on top like conventional screen-printing techniques do, sublimation prints have a softer touch.

Table 1 below provides a comparison between sublimation printing and other commonly used textile printing methods:

| Print Method | Color Fastness | Fabric Suitability | Environmental Impact |

|---|---|---|---|

| Sublimation | Excellent | Suitable for all | Minimal |

| Screen Printing | Good | Limited to certain | Moderate |

| Digital Printing | Varies | Suitable for most | Low |

Table 1: Comparison of sublimation printing with other textile printing methods.

In conclusion, the applications of sublimation printing in nonwovens are extensive and diverse. Its ability to produce vivid and long-lasting designs on various fabrics makes it a favored choice among manufacturers seeking high-quality prints that stand out. Furthermore, its eco-friendly nature and soft feel make it an appealing option from both environmental and consumer perspectives. As we move forward, the next section will delve into a comparative analysis between sublimation printing and other popular printing techniques, shedding light on their respective strengths and limitations.